Спецкрепёж / Каталоги BAER Vertriebs GmbH

BaerCoil® Threading Tools for Wire Thread Inserts

BaerCoil® Taps differ from standard taps dimensionally. They have a larger diameter but the same pitch as a standard tap in order to accommodate the wire thread insert.

| Bottoming Taps | |||||

|

| Taps, sets of 2 pcs. | ||||

|

| Taps with pilot nose, for spark plug | |||||

|

|||||

| Machine taps - ECO | ||||

|

| Machine Tap - PRO | ||||

|

| Fluteless machine taps (forming taps) | ||||

|

| Solid carbide drill thread milling cutters | ||||

|

| Precision Thread Gauges | ||||

|

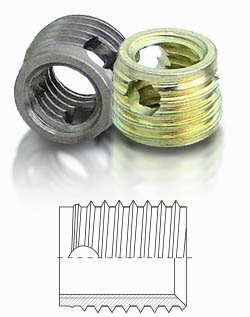

BaerFix® Thread Inserts

BaerFix® Thread Inserts for thread reinforcement and thread repair

| BaerFix® self-tapping Thread Inserts with cutting slots | |||

|

| BaerFix® self-tapping Thread Inserts with cutting holes | ||||

|

| Further product range - on request | |||

|

BaerCoil® Wire Thread Inserts

BaerCoil® Wire Thread Inserts for thread reinforcement and thread repair.

| BaerCoil® Wire Thread Inserts - Type: "free running" | ||||

|

| BaerCoil® Wire Thread Inserts - Type: ,,screw grip" (screw locking) | ||||

|

.gif)

Поделиться: